At present, mainstream printing is divided into digital printing and offset printing.

Digital printing uses inkjet technology. Inkjet technology has a history of more than 100 years. Its working method is to push tiny droplets of ink onto the substrate.

1) The advantage is that no printing plate is required, and the electronic file is directly output. Convenient, fast, flexible and efficient, suitable for printing small batches of personalized content.

2) The disadvantage is that it is printed in large quantities and the cost per piece is higher. The batch quality stability is slightly weaker.Inkjet technology causes 10% color difference.

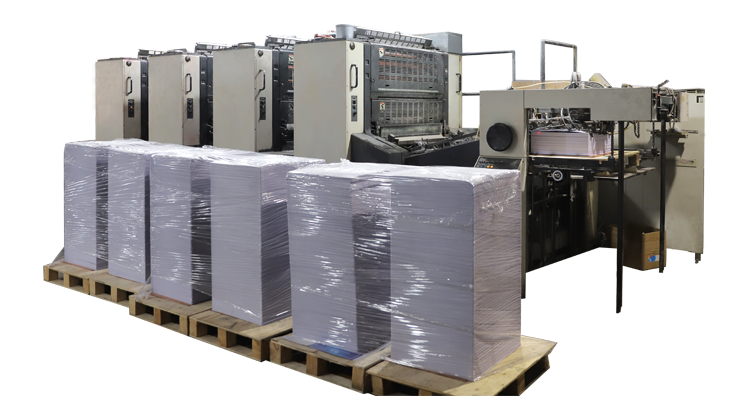

Offset printing process begins with the printer burning the design onto metal plates, making one for each color. Then, the design is transferred from the plates onto rubber rolls. After the different colors of ink are spread onto the rubber, the paper is run between the rolls. The printing paper goes through all of the rolls while layering on color and produces the final image.

1) The advantage is that it is more economical, suitable for mass printing, and the quality is stable. High color fidelity. Can print on almost any type of material.

2) The disadvantage is that the process is complicated and not suitable for small batch operations. Only the same content can be printed at a time.

Internationally well-known offset press brands: Germany Gaobao, Germany Heidelberg, Germany Roland, Japan Lithrone, Japan Mitsubishi, Japan Komori, Japan Akiyama.

Usually digital printing is adopted for small batch production or proofing.Offset printing is adopted for mass production.

Since the development of the printing industry, the integration of offset printing and digital printing technology has become the norm. It is the trend of the future.

If want to know more about factory production cards, please subscribe to RDCard.